Fresh air matters in every building, but bringing outdoor air inside has always come with a cost. In the UAE, where air conditioning systems run continuously for most of the year, traditional ventilation methods waste significant energy by exhausting conditioned air and replacing it with hot, humid outdoor air. This forces HVAC systems to work harder, driving up electricity bills while reducing equipment lifespan.

Energy recovery ventilators solve this problem through heat exchange technology. These systems recover thermal energy from exhaust air and transfer it to incoming fresh air. The result is continuous ventilation that maintains indoor air quality without the energy penalty associated with conventional outdoor air intake. For commercial buildings, industrial facilities and residential properties across Dubai and the wider Emirates, this technology delivers measurable reductions in cooling costs while meeting ventilation standards.

Operating Principles Behind Energy Recovery

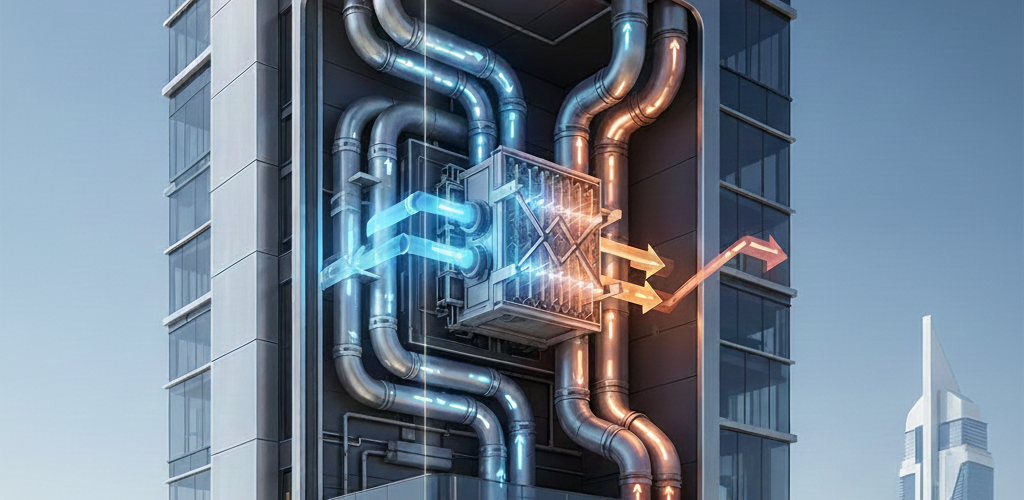

An energy recovery ventilator contains two airstreams that never mix. Stale indoor air passes through one side of a heat exchanger while fresh outdoor air flows through the other. The exchanger transfers heat and moisture between these streams without allowing air to cross-contaminate. During UAE summers, hot incoming air releases heat to cooler exhaust air before entering the building. This pre-cooling reduces the load on air conditioning systems.

The heat exchange core uses thin plates or rotating wheels made from materials with high thermal conductivity. Air passages alternate between supply and exhaust streams, creating maximum surface area for energy transfer. Some systems recover only sensible heat, while others capture both sensible and latent energy by transferring moisture along with temperature. The choice depends on climate conditions and building requirements.

Distinguishing Energy Recovery from Standard Ventilation

Traditional mechanical ventilation dumps conditioned indoor air outdoors while pulling in unconditioned outside air. This approach guarantees fresh air but ignores the energy already spent cooling or heating the exhaust stream. Buildings must condition 100 percent of incoming ventilation air from ambient temperature, creating substantial and continuous HVAC loads.

Energy recovery ventilators capture 60 to 80 percent of the cooling or heating energy from exhaust air and apply it to incoming fresh air. Instead of conditioning outdoor air from 45 degrees Celsius, the HVAC system receives supply air already pre-conditioned to 30 degrees or lower. This fundamental difference translates directly into reduced compressor runtime, lower electricity consumption and extended equipment service intervals.

Application Scenarios Across UAE Building Types

Office buildings with high occupancy densities require substantial outdoor air to maintain CO2 levels and prevent stuffiness. Without energy recovery, this ventilation demand becomes one of the largest HVAC loads. Installing energy recovery ventilators in office towers allows building managers to meet ventilation codes while containing operational costs.

Hotels and hospitality facilities face similar challenges with the added complexity of variable occupancy patterns. Guest rooms need fresh air, but traditional ventilation systems either run continuously or create uncomfortable conditions when outdoor air dampers open. Energy recovery provides consistent fresh air delivery with minimal impact on room temperatures or humidity levels.

Industrial and manufacturing spaces often generate heat, odors or airborne particles requiring continuous exhaust. These facilities cannot recirculate contaminated air, making energy recovery particularly valuable. The systems capture waste heat from production areas and use it to pre-condition makeup air, recovering energy that would otherwise escape through exhaust stacks.

Climate Considerations for UAE Installations

UAE summer conditions create extreme demands on cooling systems. Outdoor air enters buildings at temperatures exceeding 45 degrees Celsius with relative humidity often above 70 percent near coastal areas. Conventional ventilation introduces massive sensible and latent loads that stress chillers and increase electricity demand during peak rate periods.

Energy recovery ventilators designed for hot, humid climates use materials and configurations optimized for moisture transfer. These systems not only cool incoming air but also remove humidity before it enters occupied spaces. This dual benefit reduces both cooling coil loads and the condensate removal burden on air handling equipment.

During brief winter months when outdoor temperatures drop, the same energy recovery systems operate in reverse. They transfer heat from exhaust air to incoming fresh air, providing free heating that reduces or eliminates heating system operation. This bidirectional capability maximizes annual energy savings across all seasons.

Sizing and Capacity Determination

Proper sizing begins with calculating required outdoor air based on occupancy, building area and ventilation standards. UAE buildings typically follow ASHRAE Standard 62.1 or local adaptations specifying minimum ventilation rates. These requirements establish the airflow capacity needed from energy recovery equipment.

The next consideration involves matching recovery efficiency to project economics. Higher efficiency units cost more upfront but deliver greater annual savings. Building owners must balance equipment investment against operational cost reductions to determine optimal efficiency levels. Projects with high electricity rates or long operating hours typically justify premium efficiency systems.

Physical space availability affects equipment selection. Some energy recovery ventilators integrate directly into air handling units while others require separate installation with ductwork connections. Ceiling height, mechanical room layout and structural considerations all influence which configuration works best for a specific building.

Maintenance Requirements and Procedures

Heat exchange cores accumulate dust and particles over time, reducing airflow and recovery efficiency. Regular inspection schedules should include visual checks for buildup and measurement of pressure drop across the exchanger. Most manufacturers specify cleaning intervals based on environmental conditions and operating hours.

Plate-style exchangers can often be removed and washed with water or mild detergent solutions. Rotary wheel designs may require specialized cleaning procedures or professional service. Establishing maintenance protocols during system commissioning ensures sustained performance throughout equipment service life.

Air filters protecting the energy recovery unit need replacement on schedules matching building conditions. Dubai’s dust-laden environment may require more frequent filter changes than manufacturers’ standard recommendations. Monitoring filter pressure drop provides objective

Frequently Asked Questions

Do energy recovery ventilators remove pollutants from outdoor air?

Energy recovery units transfer heat and moisture but do not filter particulates or gases. Buildings require separate filtration systems to remove dust, pollen or pollutants from supply air. Most installations incorporate filters upstream of the energy recovery equipment to protect heat exchangers and maintain indoor air quality.

What efficiency improvements can UAE buildings expect?

Typical installations reduce outdoor air conditioning loads by 60 to 75 percent compared to conventional ventilation. Actual savings depend on climate conditions, operating schedules and system efficiency ratings. Buildings with high ventilation requirements see proportionally greater benefits than those with minimal outdoor air needs.

Can these systems work with existing HVAC equipment?

Yes. Energy recovery ventilators integrate with most commercial HVAC configurations. Retrofit installations connect to existing supply and exhaust ductwork while new construction incorporates them during system design. The key requirement is adequate space for equipment and duct routing to connect all four air streams.

Making Intelligent Ventilation Decisions

Every building needs fresh air, but not every building pays attention to how much energy that fresh air consumes. Energy recovery ventilators transform ventilation from a necessary cost into an efficiency opportunity. By capturing waste energy from exhaust air, these systems deliver code-compliant ventilation while protecting profit margins from excessive utility expenses.

For UAE facilities committed to operational efficiency and occupant comfort, energy recovery represents mature technology with proven returns. The systems work continuously in background operations, requiring minimal attention while delivering measurable value month after month. When electricity costs and environmental performance matter, intelligent ventilation solutions deserve serious consideration.