Introduction

In high-density urban developments, noise pollution isn’t limited to external sources; it often originates within the building itself. Sounds such as rushing water, water hammer vibrations, and HVAC mechanical hum can significantly impact occupant comfort.

Pipe acoustic lagging is a specialized engineering solution designed to control these disturbances, ensuring that mechanical systems remain effective without being audible.

What Is Pipe Acoustic Lagging?

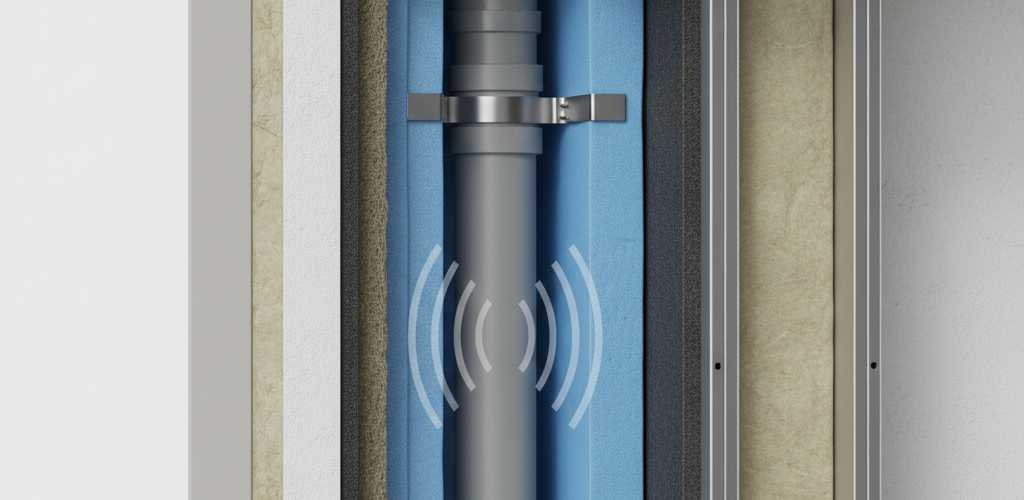

Pipe acoustic lagging is a multi-layered insulation system applied around internal pipework.

Unlike standard thermal insulation, which focuses only on temperature control, acoustic lagging is specifically engineered to:

- Block airborne noise

- Reduce structural vibration

- Minimize sound transmission through walls and floors

How Pipe Acoustic Lagging Works: The “Mass–Barrier” Principle

Effective acoustic lagging operates through a three-stage mechanical process:

1. Decoupling (The Spacer Layer)

- An inner layer of convoluted foam or mineral wool

- Separates the vibrating pipe from the outer barrier

- Prevents direct transmission of structural vibration

2. Sound Blocking (The Mass Layer)

- A dense outer layer, typically Mass Loaded Vinyl (MLV)

- Acts as a noise shield

- Reflects and blocks sound waves from escaping

3. Sound Absorption

- Porous inner materials trap sound energy

- Converts sound into negligible heat

- Reduces resonance within wall cavities

Why Construction Leaders Prioritize Acoustic Lagging

1. Compliance With Building Codes

- Mandatory decibel (dB) limits in many regions

- Essential for wastewater and rainwater pipe compliance

- Supports green building and sustainability standards

2. High-Performance Living & Working Environments

Residential Buildings

- Eliminates flushing and drainage noise near living spaces

Healthcare Facilities

- Supports patient recovery by maintaining quiet environments

Hotels & Hospitality

- Improves guest satisfaction and star-rating benchmarks

3. Protection of Property Value

- Noise-free buildings are perceived as higher quality

- Enhances marketability and long-term asset value

- Prevents costly retrofitting after construction

Common Applications of Pipe Acoustic Lagging

Acoustic lagging is particularly critical for:

- PVC Wastewater Pipes

- Lightweight construction amplifies noise transmission

- Rainwater Downpipes

- High-impact noise during heavy rainfall

- HVAC Ducting

- Prevents breakout noise from high-velocity airflow

Professional Installation: The Key to Effectiveness

Even minor installation errors can compromise acoustic performance. Small gaps may cause noise leakage and reduce the system’s overall sound reduction rating (Rw).

Best-Practice Installation Guidelines

- Overlap All Joints

- Minimum 50 mm overlap on longitudinal and radial joints

- Seal With Acoustic Foil Tape

- Ensures airtightness and prevents sound escape

- Special Attention to Bends & T-Joints

- High-impact noise zones

- Require meticulous wrapping with no material thinning

Conclusion: Designing for the Ears, Not Just the Eyes

While modern architecture often emphasizes visual appeal, true building quality is defined by acoustic comfort. Pipe acoustic lagging is a critical investment that transforms functional structures into premium, tranquil spaces.

Integrating acoustic lagging during construction ensures compliance, comfort, and long-term value, delivering buildings that are not only seen but quietly experienced.